Electro-Coagulation (EC)

WHAT IS ELECTRO-COAGULATION (EC) ?

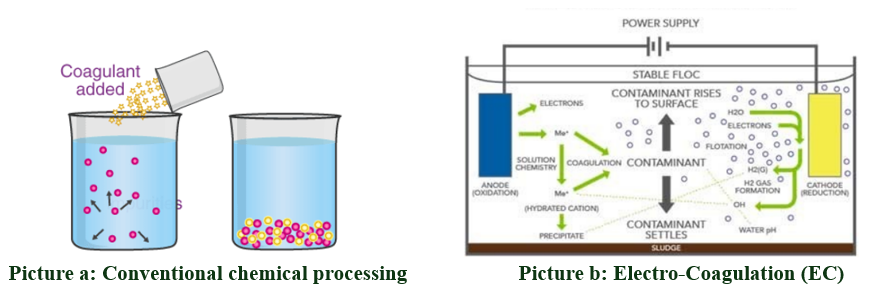

Electro Coagulation (EC) is an electrochemical method for treating polluted water, a solution patented in India and the United States by Confident Engineering India Private Limited and has been successfully applied for more than 20 years with more than 100 projects all around the world. The electro-coagulation process is very similar to conventional chemical processing, the difference is that in conventional chemical processing, coagulants are added such as alum, iron alum, PAC, decolorizer, activated carbon,... then Electrocoagulation uses electrical energy.

The electrocoagulation reactor consists of a tank of submerged electrodes (anode and cathode) connected together to a DC power source. When a certain voltage between the electrodes is reached, the direct current will corrode the metal positive electrode (anode) (usually aluminum or iron) to release Al ions or Fe ions into the solution. These ions create a stable floc that allows the mechanical removal of contaminants by: air flotation, gravity sedimentation or mechanical filtration.

PRINCIPLE OF REACTION

- When electrolysis of aluminum or iron electrodes the following processes occur:

Al → Al3+ + 3e- Fe → Fe2+ + 2e-

- The resulting aluminum and iron cations combine with OH- ions present in water to form aluminum or iron hydroxides according to the following reaction equations:

Al3+ + 3OH- → Al(OH)3 Fe2+ + 2OH- → Fe(OH)2

- At the cathode in the Electrocoagulation tank, hydrogen gas bubbles are formed according to the reaction:

H2O + 2e- → H2 + 2OH-

- These metal hydroxides will participate in polymerization reactions, removing pollutants by adsorption, complexation or precipitation.

Al(OH)3 → (OH)2Al-O-Al(OH)2 + H2O Fe(OH)2→(OH)Fe-O-Fe(OH)+H2O

Electrocoagulation produces several distinct electrochemical results independently. These observed reactions can be explained as follows:

- Seeding: resulting from the anode reduction of metal ions that become new central for larger, stable, insoluble complexes that precipitate as complex metal oxides.

- Emulsion breaking: Oxygen and hydrogen ions bond to the water-accepting sites of the oil molecule creating insoluble complexes that separate water from pesticides and herbicides

- Bleaching: The oxygen ions produced oxidize dyes, cyanide, bacterial viruses and biological hazards

- Electron Flooding: of water removes the polarizing effect of the water complex, causing colloids to precipitate and the rise of electrons creates osmotic pressure that ruptures bacteria, cysts and viruses.

- Oxidation Reduction: Reactions are forced to their natural endpoint in an electrolysis chamber (EC) which accelerates the natural processes that occur in wet chemistry

- EC induced pH swings towards neutral

PRINCIPLE OF REACTION

In an Electro-Coagulation tank, electric current provides electromotive force to drive chemical reactions, forming electromagnetic fields that can change the physical and chemical properties of water and contaminants. The treatment sequence of an Electro-Coagulation reaction tank is as follows:

- The water flow to be treated is introduced into the bottom of the chamber and evenly dispersed moving upward through the electrodes.

- Direct current (Vdc) is applied to the tank by attaching positive (+) and negative (-) leads to the first and last terminals in the tank.

- The liquid then becomes a conductor, allowing direct current to pass freely throughout the chamber.

- The electrodes respond to electric current by releasing charged metal ions into the flow.

- The influx of electrons enters the stream and will neutralize the charged pollution particles, causing them to be pulled out of suspension and removed by some secondary separation technique.

FEATURES OF ELECTRO-COAGULATION

Electro-Coagulation is a unique and latest technology that has been successfully implemented in many different countries. Confident's Electro-Coagulation features are as follows:

- No addition of chemicals for coagulant

- Improved with very low operating costs

- Less requirement of space and civil construction

- Very less solid waste (sludge) generation

- Simple, easy to operate and maintain

- Ideal pre-processing step for UF, NF or RO systems

- Iron or Aluminum electrodes interchangeable

- Produces quality water with small footprint and no moving parts

ADVANTAGES OF CONFIDENT'S ELECTRO-COAGULATION

Confident is engaged in developing and manufacturing customized Electrocoagulation (EC) technology for Wastewater Treatment Projects. Advantages of Confident's EC technology are as follows:

Legal advantages:

• Patent holder in India and the United States.

• Avoid legal risks because the technology is internationally recognized and protected.

• Traceability and quality are guaranteed.

Techno advantages:

|

|

|

|

|

|

|

|

|

|

|

|

APPLICATION OF ELECTRO-COAGULATION

The electrolysis process is applicable to most manufacturing industries:

- Textile Processing

- Pharmaceutical

- Paper

- Slaughter House

- Chemical Industries

- Dairy & Food Processing

- Mining Industry

- Leather Industry

- Oil & Gas

- Distilleries

- Domestic Waste Water

- Carwash, Hospitall & Laundry

- Heavy metals

- Fish Processing

REFERENCE RESULTS

Contact us to exchange more information in each specific case

PANATECH is the exclusive distributor of CONFIDENT ENGINEERING in Vietnam with Electrolysis patent certification in India and the United States. The electrolyzers are designed and manufactured entirely in India. Models come in many sizes for different treatment capacities and types of wastewater, allowing for easy adjustment if there are fluctuations in wastewater flow and quality.

Contact PANATECH now to consult and find the best solution for you!

PANATECH TECHNOLOGY ENGINEERING JOINT STOCK COMPANY

Hotline: 028. 22000212

Add: 59 Street no.3, An Khanh Ward, Thu Duc City, HCM City